Design and Engineering

Custom-engineered designs tailored to your process

Integrated mechanical, electrical, and architectural planning

Digital modelling and BIM for precision

Designs compliant with global cleanroom standards

Our engineering expertise makes compliance seamless.

The cleanroom design and engineering phase is where innovation becomes reality — transforming concepts into fully compliant, buildable solutions. At Modular Clean Air, our design team goes far beyond producing technical drawings. We create modular cleanroom designs that are practical, efficient, and precisely optimised for your specific operational processes.

By seamlessly integrating architectural elements with HVAC, filtration, and utility systems, we develop environments that uphold the highest standards of contamination control whilst ensuring smooth and efficient workflow.

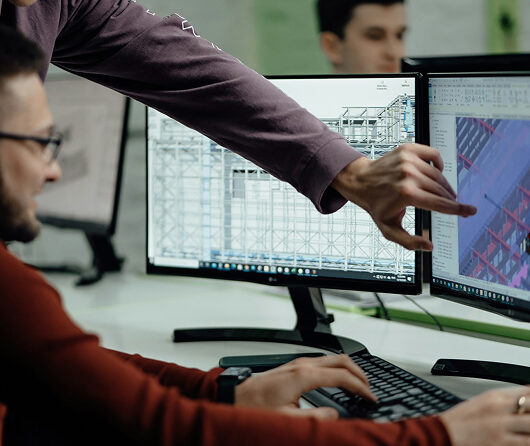

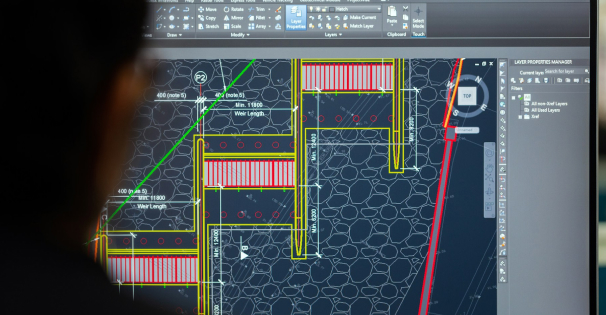

Our engineers employ advanced digital design technologies, including Building Information Modelling (BIM), to eliminate clashes, optimise layouts, and guarantee constructability from the outset. Each design undergoes meticulous review against all relevant cleanroom standards — including ISO 14644 and GMP Annex 1 compliance — to ensure complete regulatory alignment.

Whether your requirement is for an ISO Class 5 cleanroom in microelectronics or a GMP Grade C suite for pharmaceutical manufacturing, Modular Clean Air ensures that every element is engineered to deliver long-term performance, reliability, and compliance.

-

3D modelling for clash detection

-

Energy-efficient HVAC planning

-

Ergonomic workflow layouts

-

Material and contamination control

Seamless Collaboration with Stakeholders

Cleanroom projects typically involve a diverse range of stakeholders — from architects and contractors to regulatory auditors and facility operators. At Modular Clean Air, we act as the central point of coordination throughout the design and engineering stages, ensuring that every viewpoint is captured and integrated into a single, unified plan.

We recognise that differing priorities can lead to delays or misaligned outcomes. That is why our design process is inherently collaborative, built upon open communication and shared understanding. Our engineers work directly with your team to validate layouts, run airflow simulations, and confirm technical specifications, ensuring every design decision is both compliant and practical for day-to-day operation.

By fostering transparency and alignment from the outset, we prevent costly design revisions and minimise the issues that often arise during installation or validation. The result is a cleanroom design that integrates seamlessly with your facility, supports your staff, and satisfies the most stringent regulatory standards.

Get a quote

Contact us to get a quote on your project

"*" indicates required fields

Importance of Cleanroom Design

A well-engineered cleanroom design forms the backbone of effective contamination control. Poor design decisions — such as inefficient airflow, inadequate pressure differentials, or poorly positioned entry points — can compromise compliance and expose production to unnecessary risk.

At Modular Clean Air, our design and build services eliminate these challenges through engineering precision and technical excellence. Every detail is considered to achieve the perfect balance between performance, practicality, and cost efficiency.

Our design philosophy prioritises energy efficiency, ergonomic workflow, and maintainability, helping to reduce long-term operational costs whilst maintaining full regulatory compliance.

Ultimately, good design is about far more than passing validation — it is about creating a safe, reliable, and high-performing environment that consistently supports your production objectives and protects the integrity of your operations.

Industry-Specific Cleanroom Design & Engineering

Each industry presents its own distinct challenges and regulatory expectations — and Modular Clean Air’s engineering team possesses the expertise to meet them all.

Pharmaceutical and biotechnology facilities often require strict zoning and differential pressure cascades to maintain containment and product integrity. Electronics and semiconductor manufacturers demand ultra-clean ISO Class 5 environments with advanced humidity and electrostatic control. In aerospace, materials and finishes must withstand particle-sensitive assembly conditions, while medical device production frequently necessitates flexible, scalable layouts capable of adapting to evolving demand.

From the outset, our engineers incorporate these precise requirements into every design, ensuring alignment with your processes, industry standards, and regulatory frameworks. By tailoring each solution to your sector, we deliver cleanroom environments that are compliant today and adaptable for tomorrow — ensuring your facility remains fit for purpose as technology advances and regulations evolve.

The MCA Cleanroom Design Advantage

What distinguishes Modular Clean Air is the seamless combination of deep technical expertise and a practical, client-focused approach. Our cleanroom design and build services go far beyond meeting baseline compliance — we optimise every element for long-term reliability, efficiency, and sustainability.

We integrate energy-efficient HVAC strategies, low-waste modular configurations, and future-ready layouts that can adapt to evolving operational demands. Our design process is fully transparent, supported by clear documentation, digital visualisations, and open collaboration at every stage — enabling all stakeholders to make informed, confident decisions.

By investing in intelligent design from the outset, you avoid the hidden costs of retrofits, compliance failures, and operational inefficiencies. With Modular Clean Air, your cleanroom design becomes a robust foundation for successful installation, flawless validation, and sustained performance throughout the facility’s lifetime.

Cleanroom Design & Engineering Experts

Modular Clean Air are trusted experts in cleanroom design and engineering, delivering not only technical excellence but complete confidence. Our experienced design teams specialise in the full lifecycle of cleanroom development, from concept to construction, with a deep understanding of the unique challenges faced by highly regulated industries.

Our cleanroom engineering specialists guide every stage of the process — from precision HVAC design and optimised airflow modelling to strict adherence with global cleanroom standards, including ISO 14644 and GMP compliance.

As trusted partners, we create controlled environments that are engineered to perform and designed to endure, providing the assurance that every cleanroom we deliver achieves lasting reliability, compliance, and operational excellence.